The Best Guide To Wedge Barriers

Top Guidelines Of Wedge Barriers

Table of ContentsWedge Barriers - The FactsAll About Wedge Barriers

Things about Wedge Barriers

g., springtime assistance 65 )might be fixed to the end of the springtime pole 58 to make it possible for compression of the springtimes 60. As the springtimes 60 are pressed between the spring sustains 62, the spring assembly 54 generates a force acting on the web cam coupled to the spring rod 58 in a direction 66. The continuing to be pressure applied to

the cam camera deploy release wedge plate 16 may might provided given an electromechanical actuator 84 or other various other. The springtime setting up 54 and the actuator 84(e. g., electromechanical actuator)might operate with each other to convert the web cam and raise the wedge plate 16.

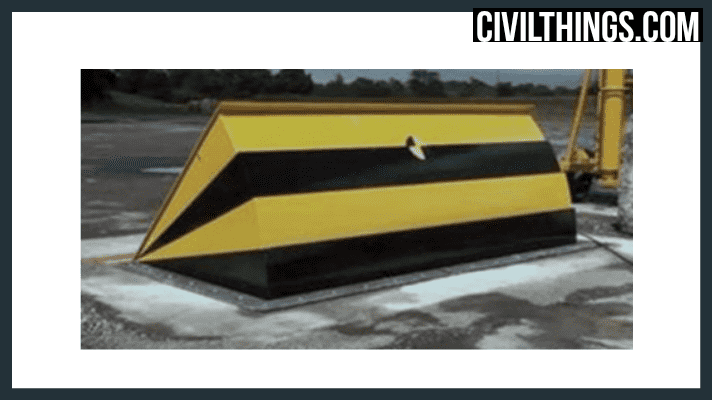

As stated over, the spring assembly 54 puts in a constant pressure on the camera, while the electromechanical actuator might be managed to exert a variable pressure on the cam, thereby making it possible for the training and decreasing( i. e., releasing and retracting )of the wedge plate 16. In particular personifications, the consistent force applied by the spring setting up 54 may be adjustable. g., electromechanical actuator) is handicapped. As will be appreciated, the springtime setting up 54 might be covered and safeguarded from particles or other aspects by a cover plate(e. g., cover plate 68 revealed in FIG. 4) that might be considerably flush with the elevated surface 38 of the structure 14. As discussed over, in the deployed position, the wedge plate 16 serves to obstruct access or travel beyond the obstacle 10. The barrier 10(e. g., the wedge plate 16 )might block pedestrians or cars from accessing a property or path. As talked about above, the obstacle 10 is connected to the support 30 safeguarded within the structure 14,

front braces 71. Therefore, the link assemblies 72 may pivot and revolve to make it possible for the collapse and extension of the linkage assemblies 72 throughout retraction and implementation of the bather 10. The linkage settings up 72 reason movement of the wedge plate 16 to be limited. As this an example, if a lorry is taking a trip towards the deployed wedge plate 16(e. For instance, in one situation, the security legs 86 might be prolonged duringmaintenance of the obstacle 10. When the security legs 86 are deployed, the safety legs 86 sustain the weight of the wedge plate 16 against her latest blog the surface 12. Consequently, the lifting device 50 might be deactivated, serviced, eliminated, replaced, etc. FIG. 5 is partial perspective view of an embodiment of the surface-mounted wedge-style barrier 10, showing the cam 80 and the webcam surfaces 82 of the lifting system 50. Specifically, two web cam surfaces 82, which are described as reduced cam surface areas 83, are placed listed below the webcam 80. The lower camera surface areas 83 may be taken care of to the surface 12 (e. For instance, the reduced cam surfaces 83 and the installing plate 85 may form a single piece that is safeguarded to the anchor 30 by bolts or other mechanical fasteners. In addition, two camera surfaces 82, which are described as top cam surfaces 87, are positioned over the cam 80 and combined to (e. In other personifications, stepping in layers or plates might be placed in between the surface area 12 and the lower webcam surfaces 83 and/or the wedge plate 16 and the upper webcam surface areas 87 As mentioned above, the cam

80 equates along the web cam surface areas 82 when the wedge plate 16 is raised from the withdrawed placement to the deployed setting. Furthermore, as pointed out above, the springtime assembly 54 (see FIG. 3 )may supply a force acting on the webcam 80 in the direction 102 through springtime pole 58, which may lower the pressure the electromechanical actuator 84 is needed to relate to the camera 80 in order to actuate and raise the wedge plate 16. 1 )to the released position(see FIG. 4). As shown, the webcam 80 consists of track wheels 104(e. g., site web rollers), which contact and translate along the webcam surface areas 82 throughout operation.